MAINTENANCE BENEFITS

New In-Production Engine

Warranty 4 years / 1500 hrs – Whichever occurs first

Worldwide logistical support

Field Technical Support

Parts availability – off the shelf parts support from P&WC

Maintenance Training

Reduced Maintenance Downtime due to the EEC Unit

The Electronic Engine Controller (EEC) is the standard engine controller used in all modern Pratt and Whitney Canada applications. It Controls all engine operations and prevents over-temps during startup. It also records the following information in the engine Data Collection Unit (DCU) to assist in maintenance practices and troubleshooting

Engine Running Time

Automatic Engine Cycle Counting (in partial cycles) leads to reduced cycle counts

Data Control unit, stores the operational history of the engine

Exceedance Monitoring

Fault Detections

Trend monitoring – In house or with P&WC software, Pratt could do the engine performance trend analysis for you.

HUMS Compatible – can adapt to aircraft HUMS system to collect engine data along with airframe data

Download all data through 3 methods, utilizing Pratt and Whitney’s Canada’s Ground Based Software System via DCU, EEC or Cockpit Port.

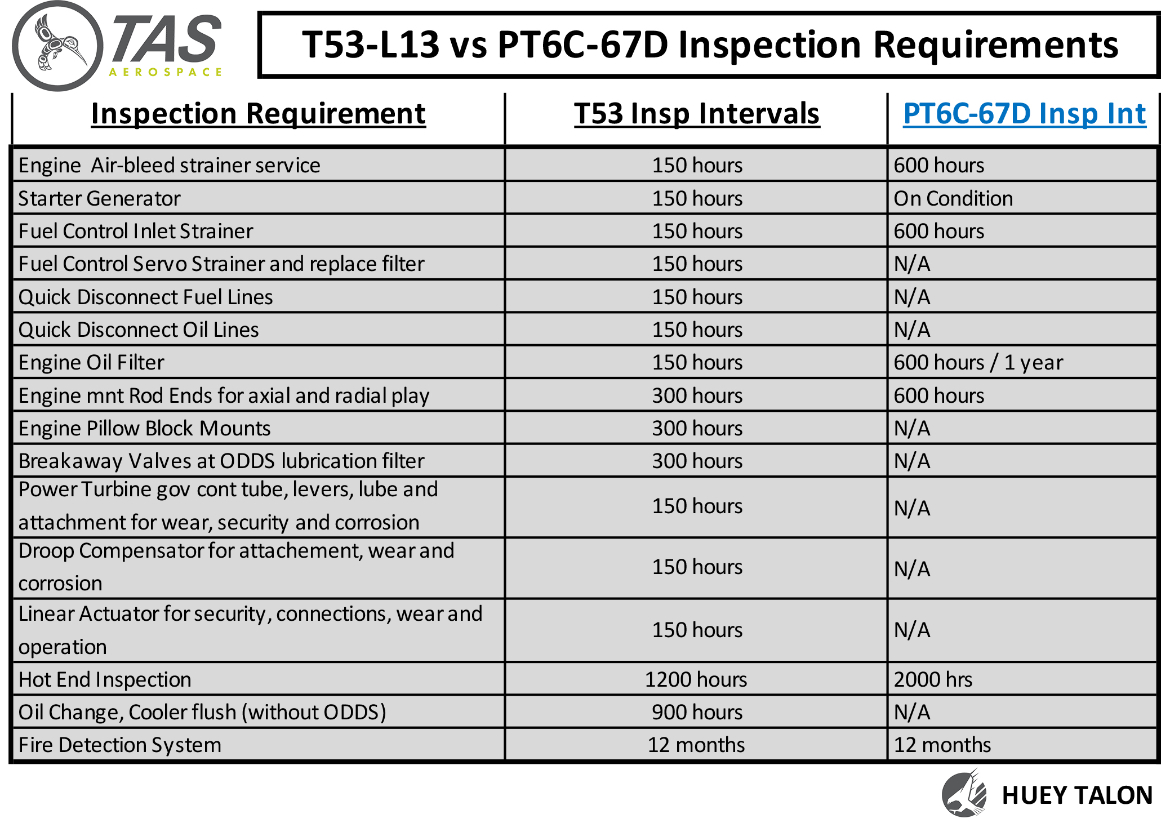

Routine Maintenance

Minimum Scheduled Maintenance with Standard Tools

Approx. 6.5 hrs. labor per 600 hrs. operation /year scheduled maintenance

No engine oil changes between overhauls

Removal of the bleed air oil cooler fan – installation of electric Fan Assembly

Reduced tailboom heat exposure

Reduced tailboom panel delimitation problems

Reduced tailboom exhaust soot

No Engine Vibrations Analysis Checks Required at installation

20 day Conversion at Customers Facility